Tungsten Copper Resistance Welding Electrodes For Industrial

Resistance Welding Electrodes for Industrial

- Product ID:Tungsten Copper Resistance Welding Electrodes For Industrial

- QQ:

- Phone: +86-13969367204

- Tel: +86-533-3819977

- Email: william@maikewelding.com

- Time: 2024-11-01 14:56:56

- Feedback

Wholesale W75 copper tungsten electrodes for resistance welding

Consisting

of pure tungsten (W) powder suspended in a matrix of copper (Cu), these

alloys are known for good thermal and electrical conductivity, low

thermal expansion, and resistance to erosion from arcing. Thus, they

are often used as electrical contacts, particularly in high voltage

applications. Most sizes and shapes can be supplied with short lead

times. We can also manufacture parts from these materials to your

specifications.

Advantages:

* High arc resistance combined with good electrical conductivity

* High thermal conductivity

* Low thermal expansion

Applications:

* Arc contacts and vacuum contacts in high/medium voltage breakers or vacuum interruptors

* Electrodes in electric spark erosion (EDM) cutting machines

* Heat sinks for passive cooling of electronic devices

* Electrodes for resistance welding

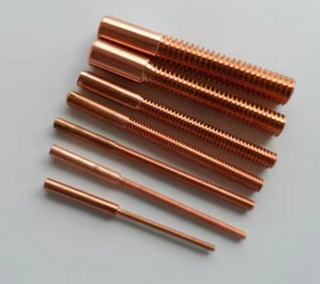

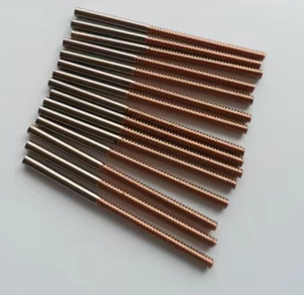

Products Show

Tungsten

copper electrodes is used to satisfy the demand of combination of

electrical conductivity resistance to arccorrosion. Tungsten Copper

Electrode are use as High electrical and High thermal conductivity in

for various welding Process. For racking contacts.electric discharge

machine and but welding etc.

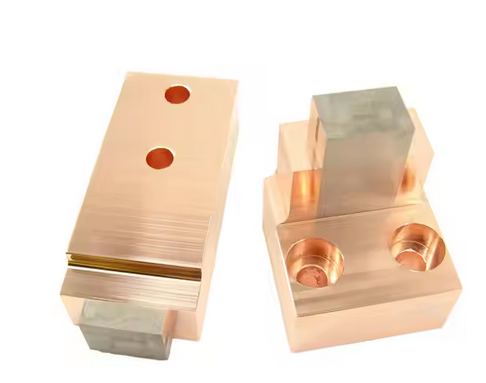

In the resistance welding process,

the parts to be joined are pressed together and heated by an electric

current until pools of molten material form at individual points between

them. This operation requires high currents and large pressing forces.

Welding

electrodes made from our refractory metals and their alloys have a

relatively high level of electrical conductivity while also exhibiting

outstanding stability at high temperatures. They therefore have a

considerably longer service life than conventional materials such as

copper and copper alloys.

Our welding electrodes made of

tungsten, molybdenum and their alloys are particularly suitable for

welding highly conductive materials such as copper. They are used in the

following processes: Spot welding, Roller welding, Projection welding,

Upset welding.

We supply 100% infiltrated tungsten-copper

comprising 75% tungsten and 25% copper for your projection welding

process according to RWMA standard. This composite brings together the

best of both materials: The strength of tungsten and the excellent

thermal and electric conductivity of copper.

CATEGORIES

LATEST NEWS

- Tungsten market continues to rise, keep an eye on long-term order releases

- The tungsten market continues to push up and become bullish

- Backend still sluggish

- Analysis Of Tungsten City: Weak Supply And Demand At The End Of The Year

- Analysis Of Tungsten City: Both Ends Of Supply And Demand Are Not Active. The Market Is As Calm As Usual.

CONTACT US

Phone: +86-533-3819977

Tel: +86-533-3819977

Email:

Add: East end of Yihe Road,Guoli Town,Huantai,district,Zibo,City,Shandong