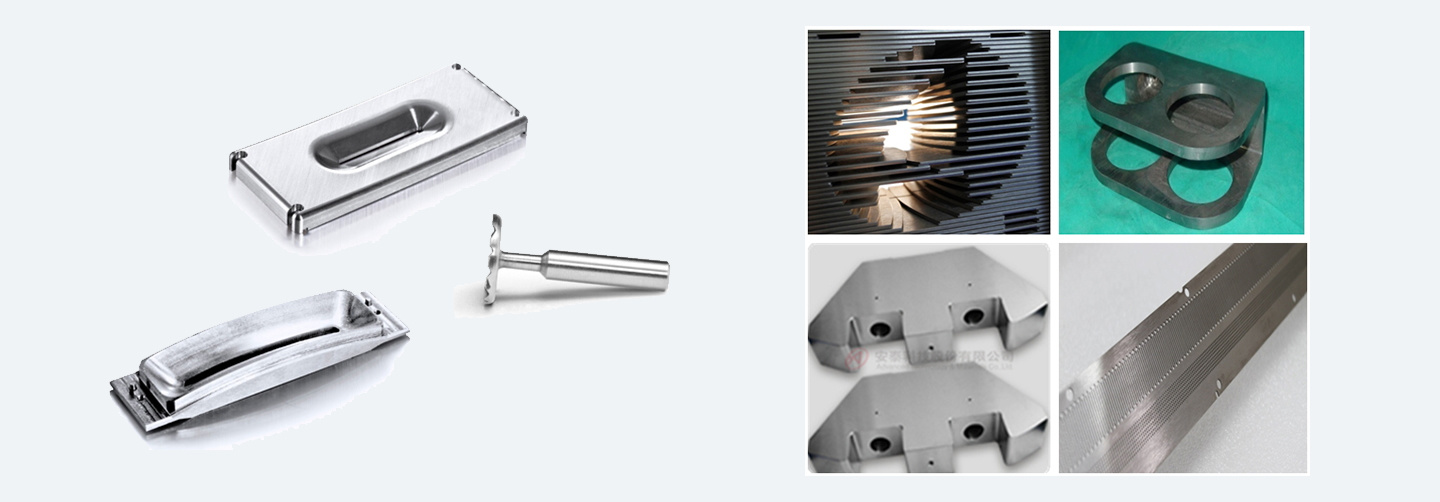

Special Shaped Tungsten Products

Special Shaped Tungsten Products

- Product ID:Special Shaped Tungsten Products

- QQ:

- Phone: +86-13969367204

- Tel: +86-533-3819977

- Email: william@maikewelding.com

- Time: 2024-07-01 17:11:30

- Feedback

Product Introduction

MAIKE TUNGSTEN has the largest deep processing capacity of tungsten and molybdenum products in China, featuring CNC machine tools, horizontal machining centers, turning, milling, planing, grinding, electrical processing and other equipment. MAIKE TUNGSTEN boasts advanced machining technology and equipment, and is able to process a variety of complex special-shaped tungsten parts.

MAIKE TUNGSTEN can process various types of tungsten products based on user requirements, while always ensuring reliable quality and on-time delivery.

Tungsten is a metallic element. Its chemical symbol is W, with an atomic number of 74 and a density of 19.35 g/cm3. China has the largest tungsten reserves in the world.

Tungsten features a high melting point, high strength and hardness, excellent high temperature performance, low resistivity, a small expansion coefficient, and a small electronic work function. It is a widely used high temperature resistant metal.

Tungsten has a high purity, going up to 99.95%.

Chinese Name | (Wu) | Chemical symbol | W |

English Name | Tungsten | Atomic mass | 183.84 |

CAS Registry Number | 7440-33-7 | Type of element | Metal |

EINECS Registry Number | 231-143-9 | Density | 19.35 g/cm³ |

Melting point | 3410 ℃ | Atomic number | 74 |

Boiling point | 5660 ℃ | Solubility in | Insoluble |

Product Application

Tungsten is a refractory metal with the highest melting point and the lowest expansion coefficient, and has high resistance to deformation at high temperatures. It is suitable for use in high-temperature furnace components in environments with extremely high temperature requirements: heat shields, heating elements, supports, etc.

Tungsten has a purity of more than 99.95%, with little pollution. It is widely used in the manufacture of electronics and electric light source industry, for example in parts for ion implantation machines, MOCVD heating elements, sputtering targets, etc.

Tungsten has a high density and can be used as a mechanical counterweight; it exhibits poor penetration, and its alloys are mostly used in medical radiation shielding components.

Product Specifications

All specifications and sizes of products can be designed and fabricated according to customer demands.

Fabrication Process

Company Advantage

The advantages of our production capacity are obvious, and meet the batch demand of our customers.

The products cover the main crystal growth furnace equipment models, and feature a wide range of customer applications.

Years experience in the R&D and preparation of refractory materials, and experience in material selection and preparation processes.

Product design upgrade and improvement capabilities, in line with the latest requirements for mainstream crystal growth furnace equipment.

CATEGORIES

LATEST NEWS

- Tungsten market continues to rise, keep an eye on long-term order releases

- The tungsten market continues to push up and become bullish

- Backend still sluggish

- Analysis Of Tungsten City: Weak Supply And Demand At The End Of The Year

- Analysis Of Tungsten City: Both Ends Of Supply And Demand Are Not Active. The Market Is As Calm As Usual.

CONTACT US

Phone: +86-533-3819977

Tel: +86-533-3819977

Email:

Add: East end of Yihe Road,Guoli Town,Huantai,district,Zibo,City,Shandong